bFRIENDS: Bene launches its first, 3D-printed, circular-production accessories collection

Launching on 11 November, bFRIENDS by Bene is a collection of desirable and intuitive desktop accessories – made from discarded food packaging. Comprising pen pots, trays and a stand for mobile devices, the collection is 3D-printed from recycled PLA, a cornstarch-derived bioplastic, diverted from landfill. At the end of the products’ lives, they can be easily returned to Bene to be recycled again – creating a complete, closed-loop production cycle.

A compelling demonstration of the viability of 3D-printing as a means of manufacturing mass-appeal consumer products, the launch marks a small but significant step forward in the global drive to shift manufacturing from linear production methods to sustainable, closed-loop systems.

The collection is the result of a remarkable three-way collaboration between Bene, its longstanding design collaborator Pearson Lloyd, and Batch.Works, a London start-up specialising in 3D-printed consumer products. In a project initiated, steered and designed by Pearson Lloyd, the three companies have come together, pooled their expertise, and developed the new line of products using locally sourced recycled post-consumer PLA from Reflow, which specialises in recycling the bioplastics used in products such as food packaging for 3D printing.

For Bene, the bFRIENDS collection is both the company’s first major foray into office accessories and its first commercial application of 3D-printing technology – making this launch the first step in what promises to be an exciting new chapter.

"The launch of bFRIENDS is exciting new territory for us, and makes Bene one of the very first furniture brands to offer a 3D-printed accessory line. Pearson Lloyd’s design brilliantly demonstrates their capacity to balance form and function, and responds honestly and elegantly to both the material and the process of 3D printing. The circular manufacturing model being pioneered by companies such as Batch.Works offers real hope for the sustainable future of design and production – and this collection is proof that it works. bFRIENDS is only the beginning." Michael Fried, Bene

A new materiality and circular-design aesthetic

bFRIENDS is a family of desktop storage solutions that combine function-led design with an endearing organic appearance. Including trays, stationery stands, pen pots and holders, clips and hooks, the collection comprises 21 products in 10 standard colours, with custom colours available on demand.

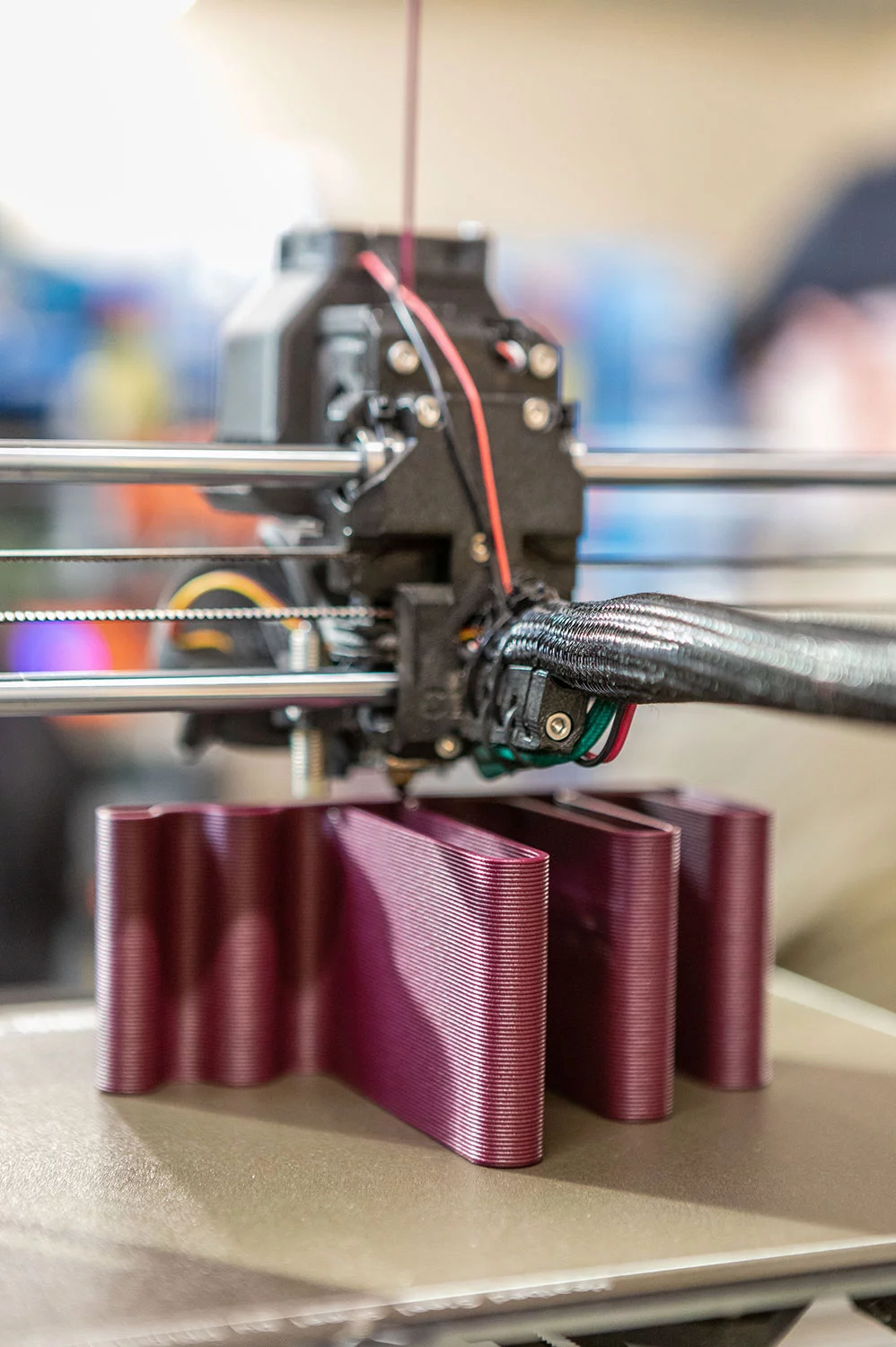

The forms within the bFRIENDS collection were designed by Pearson Lloyd to express the layer-by-layer 3D printing manufacturing process. Photography by Alex Sarginson.

The bFRIENDS name alludes variously to the eco-friendly nature of the products, the warmth of their aesthetic, and the spirit of collaboration in which they were created.

The designs clearly bear the signature look and feel of 3D printing. An additive process, 3D printing builds up the products layer by layer in a single continuous line of bioplastic, rather than cut away from a larger material block or injection moulded. Pearson Lloyd’s designs consciously imitate this process, following the logic of the single unbroken line – ‘the pen never leaves the page’ – to determine the formal language of the collection. The process of printing in layers leaves a tactile horizontal ridging on the vertical surfaces. Pearson Lloyd were determined that this should be a key design feature, and thus decided to use a larger nozzle on the printer to emphasise the ridges as each layer was formed. This also had the effect of making the products stronger and more durable, thus extending their longevity. As a result, these objects wear the story of their manufacture with pride – reminding the user of why they were made this way.

The bFRIENDS palette of 10 colours spans warm, cool and neutral tones, carefully chosen to convey an approachable and tactile appeal that complements the organic curves of the pieces without becoming loud, garish or unsubtle, and which integrates seamlessly into Bene’s existing product portfolio.

“The language and identity of the bFRIENDS collection responds closely to the manufacturing limitations of 3D printing, which we embraced fully. A single continuous line traces the silhouette of each product and truly demonstrates the additive nature of the printing process. The colour palette mirrors the physical language of the collection – both playful and rational, able to deliver bright accents or monotonal collections.” Tom Lloyd, Pearson Lloyd

The result is a collection of versatile accessories that transform the desktop into a practical, organised and engaging space, complements Bene’s furniture collection and beautifully demonstrates the commercial viability of 3D printing in the workplace market.

Low-energy, zero-waste, fossil fuel-free circular design

The 3D printing technology used to create bFRIENDS represents a hugely important step towards a genuinely circular and sustainable model of production.

Batch.Works’ process sources raw materials by intercepting a local waste stream, requires no tools in production, generates no waste itself, and manufactures on demand, minimising any need for storage or warehousing.

"3D printing has enabled us to create an entire accessory collection with no tooling whatsoever. Other processes – such as injection-moulding – demand significant amounts of embedded energy just to create the moulds and tools needed to manufacture a single item. The energy saving offered by 3D printing is extraordinary in comparison." Luke Pearson, Pearson Lloyd

Furthermore, with no need for centralised global production, bFRIENDS products can be produced via a distributed network of local manufacturing hubs, cutting shipping distances for both raw material and finished product, and significantly shortening supply chains and lead times.

Because PLA is a non-oil-based bioplastic derived from cornstarch, no fossil fuels are involved at any stage of production. This, combined with the fact that Batch.Works’ print facilities are wind-powered, means that production is energy-efficient, demanding 1.35 KW for every kilogram of printed product, and ensures that carbon emissions during production are kept close to zero.

Batch.Works’ custom 3D-printing process produces Pearson Lloyd’s bFriends collection from recycled bioplastic. Photography by Alex Sarginson.

PLA is recyclable, so any bFRIENDS product can, at the end of its life, be returned to the production cycle and reformed into a new product. The fact that all products are of a single colour and material and require no disassembly makes remanufacture especially easy, maximising material value and further extending the carbon lifecycle. Each product will be packaged with details of drop-off locations for the user to return it to the production cycle at the end of its life, thus creating a closed-loop production cycle. Alternatively, bFRIENDS products can alternatively be disposed of as part of normal household recycling.

Progressive partnership to drive innovation in workplace design

Bene and Pearson Lloyd have worked together for over 15 years and have produced a host of forward-thinking workplace collections together. Both companies are characterised by the pursuit of innovation in the workplace sector, and both share a drive to develop viable solutions to production in the face of climate emergency.

While researching eco-conscious production models, Luke Pearson and Tom Lloyd came across Batch.Works and were impressed by how the start-up was leading the way in using 3D print technology as a sustainable alternative to fossil fuels and linear production methodologies. Through its use of recycled PLA from food packaging that has been diverted from landfill, and because all its 3D-printed products are recyclable, Batch.Works is an exemplar of the circular-design revolution in action – and an ideal partner for carbon-conscious businesses such as Bene.

Pearson Lloyd mapped out the possibility for the three organisations to jointly develop a collection of desktop accessories suited for use in both workplace and domestic settings, as well as the possibility to create bespoke collections on demand.

"At Pearson Lloyd, we are developing various projects that use circular-design principles in their inception. Using 3D-printed post-consumer bioplastic fits into the new models of production and consumption that we all need to embrace in our search for viable responses to the climate emergency." Luke Pearson, Pearson Lloyd

Bringing together Bene’s resources as an international leader in workplace innovation Pearson Lloyd’s design vision, user-experience expertise and familiarity with Bene’s existing portfolio and Batch.Works’ pioneering circular production model and material understanding, bFRIENDS elegantly demonstrates the viability – indeed, the necessity – of circular-design models as a response to climate emergency.

bFRIENDS’ circular production model offers hope for the future of sustainable design and manufacturing.

Launch information

- Designed to integrate with Bene’s existing workplace furniture collections, but able to be used in conjunction with other office products, the full bFRIENDS collection launches on 11 November 2021, comprising:

- Whiteboard Pot – markers can snap on to the outside or be placed in the cavities.

- Pen Pot – with internal cavity and outside grooves to hold pens.

- Duo Pot – for pens.

- Trio Pot – for storing small items such as: pins, magnets and personal effects. Its central pinched form allows for easy pick-up.

- Pen Tray – a storage pot and phone holder, with tapered and flat faces to allow for two orientations.

- Tray S/M – to hold personal items and stationery.

- Tray L – a central vessel acts as additional storage and serves as a handle.

- Multiple trays can be assembled to form a Pixel Tray Set. The set is designed to fit into the existing Bene Pixel Tray, this highly portable combination is suited to collaborative workshop environments.

- Stand XS – for sticky notes and pens, ideal for small booth environments and for making quick notes.

- Stand S – two pen holders on either side make it perfect for shared environments such as meeting rooms.

- Stand M – for personal items and stationery with ridges that serve as a phone stand.

- Stand L – for personal items and stationery with ridges that serve as both a phone and iPad stand.

- Screen Hook S/M/L – a selection of headphone/bag hooks designed for use with existing Bene products such as desk screens, docklands enclosures, and wing chairs.

- Screen Clip S/M – designed to work with the entire range of Bene screens, the hooks slide directly onto the screen to secure loose paper and notes.

- Table Hook S/M – applied directly to the desk surface, the hook holds personal items such as bags and/or headphones and removes the risk of entangling cables.

The collection will be available from Bene dealers worldwide. Thanks to the versatility and rapid turnaround of the 3D-printing process, bespoke designs and custom colours can easily be made to order.